Optimizing Your Job Site: The Value of Pre-cut Lumber

Improving Accuracy and Reducing Waste

In the world of contracting and home building, every minute on the job site counts. Efficiency is not just a buzzword; it’s the key to maintaining profitability and staying competitive. While every professional is focused on maximizing labor and minimizing delays, a significant amount of time and money is often lost before the first nail is even driven: in the process of cutting and preparing lumber on-site.

The traditional method of buying raw stock and cutting it to size at the job site may seem like standard practice, but it introduces a host of hidden costs and inefficiencies. Smart contractors are now turning to a more streamlined solution: pre-cut lumber. By shifting the cutting process to the supplier, they are gaining a significant advantage. This guide will explore the tangible value of pre-cut lumber and how it can transform your next project.

The Hidden Costs of On-Site Cutting

Take a moment to consider how much time your team spends on tasks that don’t directly contribute to the finished build. On-site cutting, while necessary, is often a major time and money sink.

- Labor Costs: Your highly-skilled carpenters and framers are an expensive resource. Every hour they spend measuring and cutting lumber is an hour they are not framing a wall, installing a roof, or building a cabinet. Paying skilled labor for this type of repetitive, less-specialized work eats directly into your project margins.

- Tool Wear and Tear: The constant cutting of lumber puts a heavy strain on your saws and blades. The time and money spent on maintenance, blade replacements, and power consumption add up over the course of a project.

- Material Waste: Mistakes are inevitable when cutting on-site. Every inaccurate cut, every piece of mis-measured lumber, and every leftover offcut becomes expensive waste. This material waste not only increases your overall lumber cost but also adds to your disposal fees.

- Job Site Clutter and Safety Hazards: A job site filled with lumber scraps and sawdust is a less productive and more dangerous environment. Your crew has to spend valuable time cleaning up and navigating around obstacles, which can slow down work and increase the risk of accidents.

The Rustic Door & Pine Advantage: A Smarter Way to Build

At Rustic Door & Pine, we believe there is a better way. By shifting the precision cutting process to our professional millwork team, we can provide you with lumber that arrives at your job site ready to be installed. This approach offers a host of tangible benefits that directly impact your bottom line.

- Unmatched Precision and Accuracy: Our state-of-the-art milling equipment allows us to achieve a level of precision that is difficult to replicate with portable saws on a job site. Every cut is clean, accurate, and consistent, leading to a tighter, more professional build that requires less on-site fitting and adjustment.

- Reduced Labor, Boosted Productivity: When you order pre-cut lumber, your crew can focus on what they do best: building. The time saved from measuring, marking, and cutting translates to hours of productive labor. A project that might have taken a week can be finished in just a few days, allowing you to move on to the next job sooner.

- Minimal Waste, Maximum Savings: We are able to optimize our cuts to minimize waste, passing those savings directly on to you. You pay for the lumber you need, not for the scraps you throw away. This also means less debris on your job site, leading to lower disposal fees and a cleaner, safer work environment.

- Streamlined Logistics: Imagine a delivery of lumber that is organized and labeled by section or phase of the project. Our team can coordinate the delivery of pre-cut lumber in a way that makes on-site inventory management and project staging a breeze, eliminating the time wasted searching for the right piece of wood.

From Theory to Practice: Real-World Scenarios

The value of pre-cut lumber becomes even clearer in complex projects.

- Roof Framing: For a complex roof with multiple pitches and dormers, the on-site cutting of rafters and trusses can be a tedious and error-prone process. By providing pre-cut framing packages, we can reduce the time and potential for errors, ensuring the roof frame goes up quickly and accurately.

- Custom Trim and Moldings: For a whole-house trim job, cutting hundreds of pieces of baseboard, crown molding, and casing to specific lengths on-site is a labor-intensive process. By providing pre-cut trim packages, we allow your finish carpenters to get straight to installation, saving countless hours.

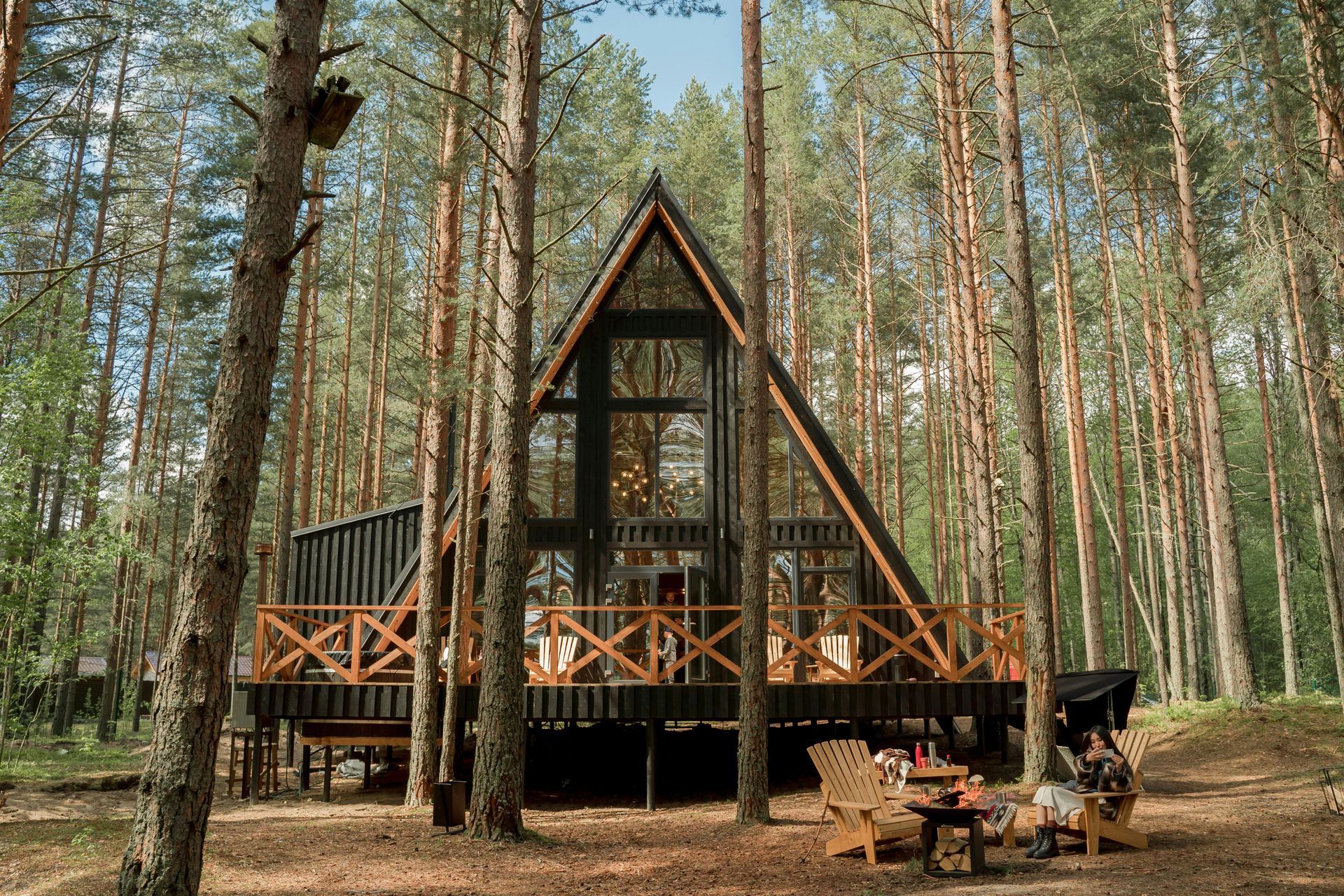

- Barn or Cabin Construction: For larger-scale projects like barns or cabins, the sheer volume of material to be cut on-site can be overwhelming. Pre-cut lumber packages can be a game-changer, transforming the construction process from a cutting operation into a more efficient assembly process.

Your Partner in Efficiency and Quality

In a market where every dollar and every day counts, optimizing your job site is no longer an option—it's a necessity. By choosing pre-cut lumber, you are making a strategic business decision that reduces labor costs, minimizes material waste, and boosts productivity.

If you are a contractor in the Central Pennsylvania area, including Mill Hall, Spring Mills, Boalsburg, Bellefonte, State College, Harrisburg, and Centre Hall, Rustic Door & Pine is ready to be your partner. We specialize in providing high-quality, pre-cut lumber that helps you build better, faster, and more profitably.

Contact us today to discuss your next project and discover how the value of pre-cut lumber can transform your business.

Order Now

Rustic Door & Pine is your source for exceptionally high quality lumber, doors, kindling and Etchwood products. Shop online or contact our team to place an order.